The construction industry has been slower to adopt technology than others, but tech usage is growing in every area of the industry. Equipment innovations have ramped up over the years, from touchscreens in cabs to telematics to autonomous machines. Jobsite safety is a target area for new tech, with original equipment manufacturers (OEMs) aiming to reduce risk for both operators and workers on-site. Around-view-monitoring and object detection are popular safety features for OEMs. Construction Business Owner spoke with Katie Voelliger, product manager at John Deere, about the company’s latest equipment solution, SmartDetect.

What is SmartDetect? How does it work, and who is the core user?

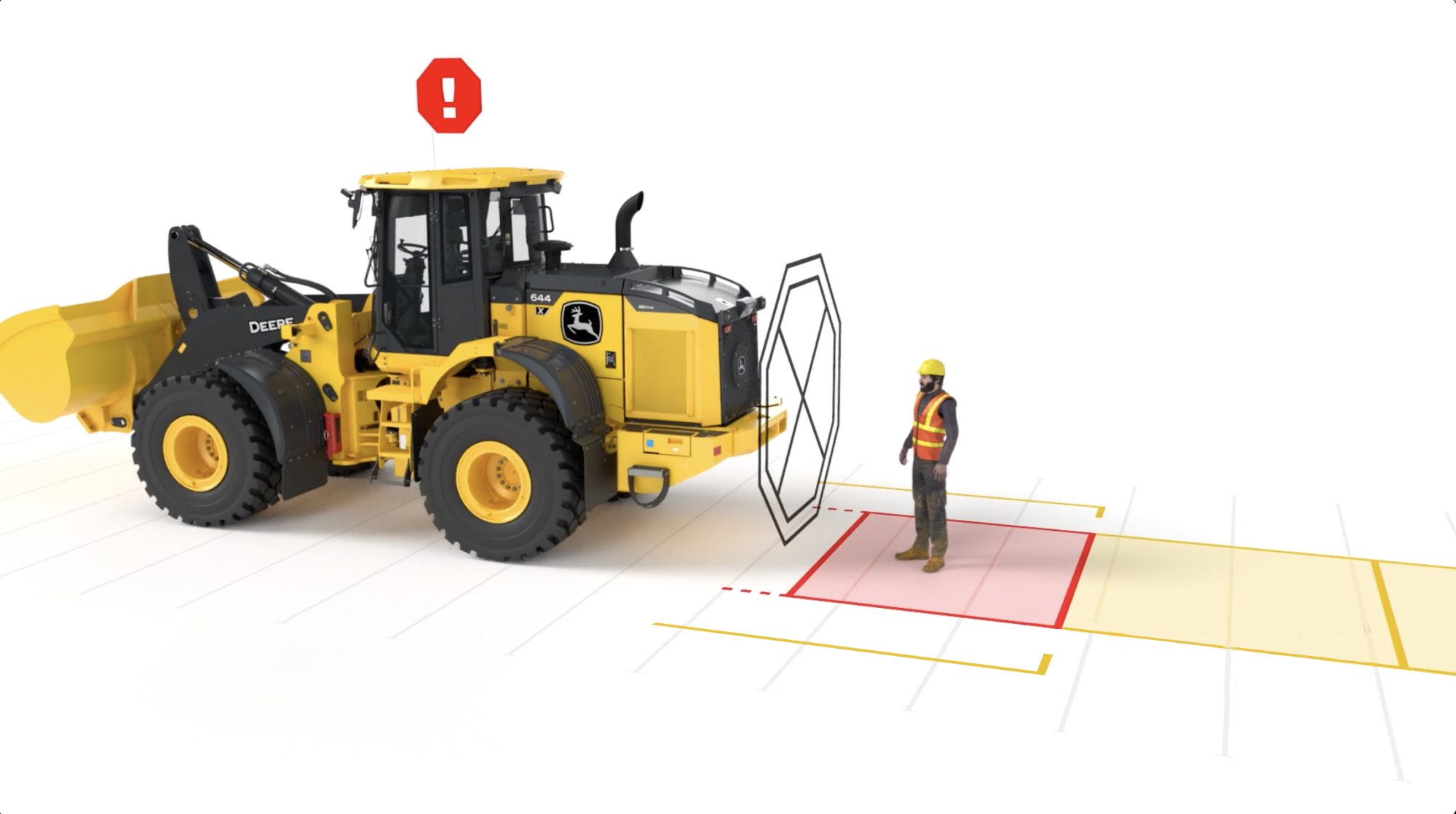

SmartDetect offers enhanced operator awareness, thanks to its strategically positioned cameras that enhance the field of view. The system features automotive-style dynamic travel path lines for reverse operations, along with object classification and visual and audio notifications, keeping operators more alert and informed. Customers have reported that SmartDetect significantly improves jobsite safety practices, boosts operator confidence and minimizes equipment damage. Utilizing stereo cameras that work in pairs, SmartDetect provides a 3D perception view to detect bystanders and objects behind the loader. The secondary G5 display delivers a live digital camera feed, alongside audible and visual alerts. The G5 display is essential for activating SmartDetect, processing video, lighting and alarm data during operation.

How does this feature enhance jobsite safety? What’s the difference between this tech and other object detection solutions?

Jobsite safety is a top priority for everyone, and customers are eager for technology solutions that help keep operators and crews safer while on the job. This new solution combines cameras and machine learning to help give operators a better view of their surroundings. SmartDetect utilizes the machine’s integrated digital cameras and a dedicated rearview high-resolution monitor to supplement operator’s jobsite visibility.

What is the most critical problem this tech is designed to fix?

SmartDetect is engineered to enhance situational awareness, empowering operators to work with confidence and providing clear visibility of their surroundings. It ensures that operators remain well-informed about their environment, facilitating safer and more efficient operations.

Is this product ideal for any particular type of project/jobsite?

The technology is particularly well-suited for busy construction sites. It excels in environments where heavy machinery operates, helping to enhance safety and efficiency. It can help monitor the presence of workers and equipment, reducing the risk of accidents and improving site management.

What else do operators need to know before using a machine equipped with SmartDetect?

Operators need to understand how SmartDetect functions, including its object-detection features and alerts. Familiarity with the G5 display is essential, as it activates the system and provides real-time information. Proper calibration for jobsite conditions is vital, along with regular checks to maintain performance. Operators should also recognize that while this tech enhances safety, it doesn’t replace the need for vigilant human oversight. Regular maintenance and software updates are important, and participating in specific training programs can help maximize the technology’s benefits for safer, more efficient operations.

How do you see machine advancements changing the way contractors work?

This type of technology is poised to transform contractor operations by enhancing efficiency, safety, and decision-making. By using advanced sensors and artificial intelligence (AI) to identify obstacles and hazards in real time, SmartDetect allows for more autonomous machine operation, reducing the need for constant oversight and improving jobsite safety. Additionally, it collects valuable data on site conditions and machine performance, enabling contractors to optimize workflows, predict maintenance needs and make informed decisions.

What was the development process like for this solution?

The development process for SmartDetect involved several key stages, reflecting a focus on innovation, safety and operator experience. Extensive research was conducted to identify the specific needs of operators and the challenges faced in jobsite safety.

Teams across the construction and forestry division as well as our Intelligent Solutions Group came together to work on this. As technology continues to grow and evolve from digital to embedded, the challenge was clear. John Deere needed to develop an AI/computer vision machine learning (CVML) model in the construction space. It relies on images taken from jobsites. No two jobsites are alike, so developing a dataset that can perform to our customers’ expectations in varying environments and conditions was a challenge the team had to work through. They were able to come up with enough common environments to make the AI/CVML system learn about a jobsite.

Additionally, customers were providing feedback throughout the entire process. We needed to make sure what we brought to market not only met, but exceeded, customers’ expectations.

What trends have you observed in machine innovation? Do you think user safety will be a driving factor in future products?

User safety is likely to be a key driving factor in the development of future products, especially in construction. As technology advances, there is a growing emphasis on integrating safety features that not only protect operators but also enhance overall jobsite safety.