CHICAGO (Dec. 2, 2024) — BuiltWorlds’ recently released 2024 Offsite Construction Annual Benchmarking Report paints the sector as one in the midst of an evolution, revealing widespread internal prioritization of off-site construction as well as increasingly diversified facilities and methods.

“Off-site construction, particularly prefabrication and modularization, is experiencing rapid growth and innovation across residential and commercial applications,” the report reads. “As more and more groups look to implement offsite construction into their daily operations, the need for dedicated teams and facilities to deliver is growing in unison.”

Data Shows More Off-Site-Dedicated Teams & Diversified Facilities

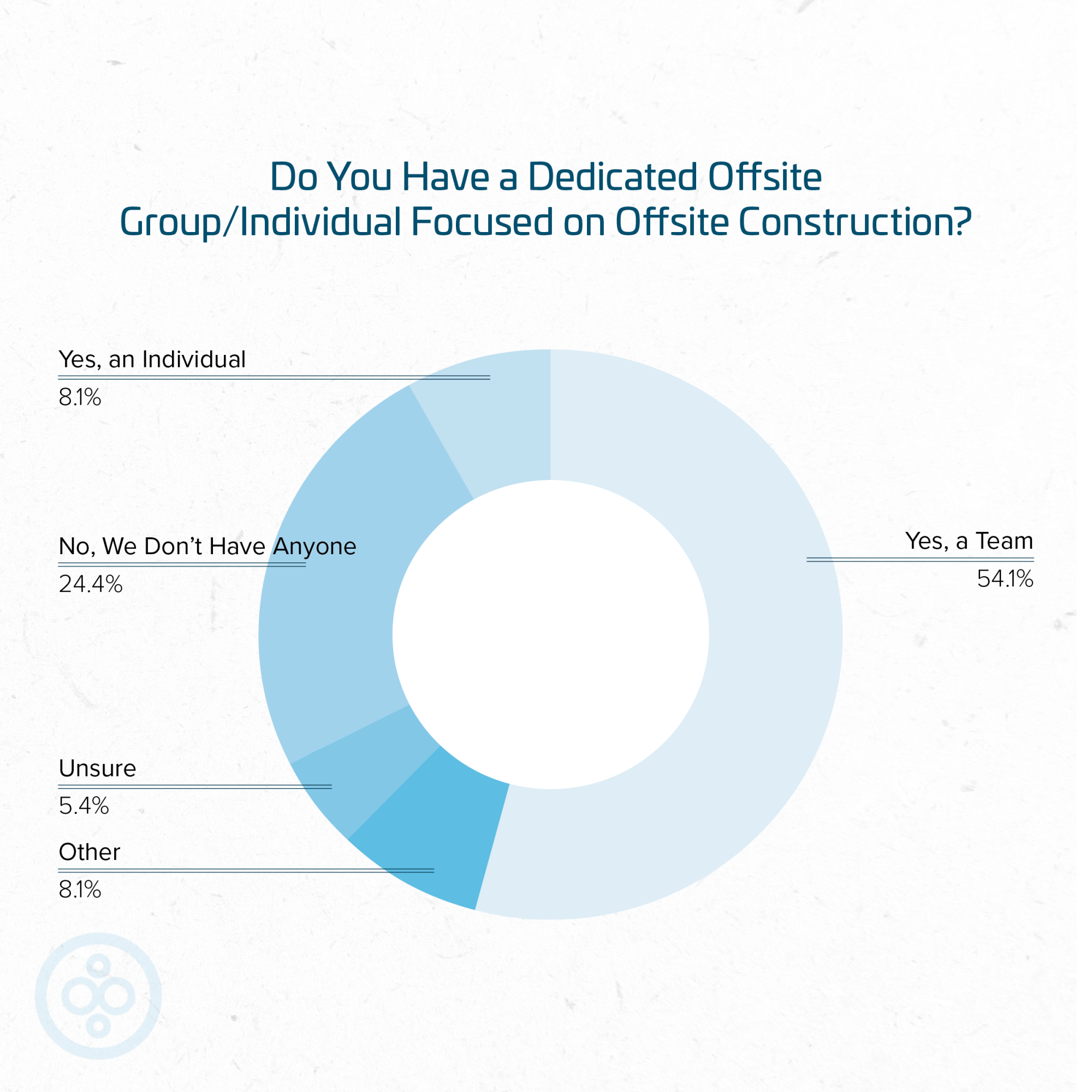

The report showed that from 2023 to 2024, contractors with teams dedicated to off-site construction jumped from 46% to 54%. However, while respondents reported an increase of off-site-specific staff, that didn’t translate to an increase in dedicated facilities.

The report reads: “Despite growing offsite teams and adoption of the delivery method more generally, data from the 2024 annual survey shows no meaningful change in the percentage of respondents with their own facilities for prefabrication and modularization.”

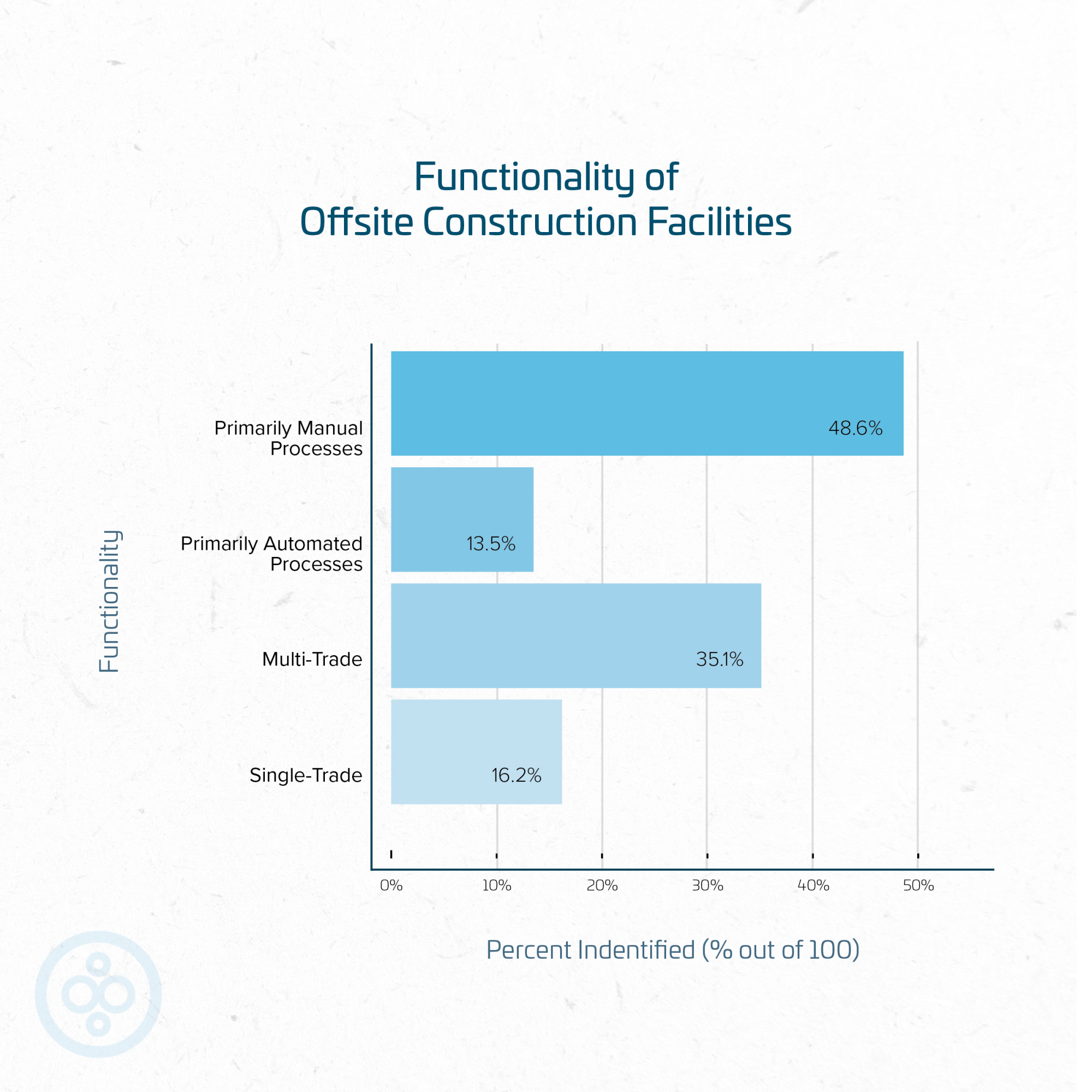

Still, despite negligible growth in contractor-owned off-site facilities, the functionality of those existing facilities does appear to be expanding. Since the last survey, single-trade facilities have decreased, falling from 24.4% in 2023 to 16.2% in 2024, while multi-trade facilities have significantly increased, rising from 22.2% to now 35.1%.

“By including multiple trades in a prefab or modular facility, builders can streamline construction processes, improve efficiency and coordination across trades, reducing overall costs — all of which impact a project's speed to market,” says BuiltWorlds Senior Research Analyst Sean Wrenn, who authored the report. “Ultimately, organizations distancing themselves from single-trade facilities enable them to consolidate workflows, reduce redundancy, and improve integration across trades. While the initial investment may be higher, the long-term benefits in efficiency, quality and cost savings often outweigh those of single-trade facilities.”

Where Off-Site Construction Is Strongest

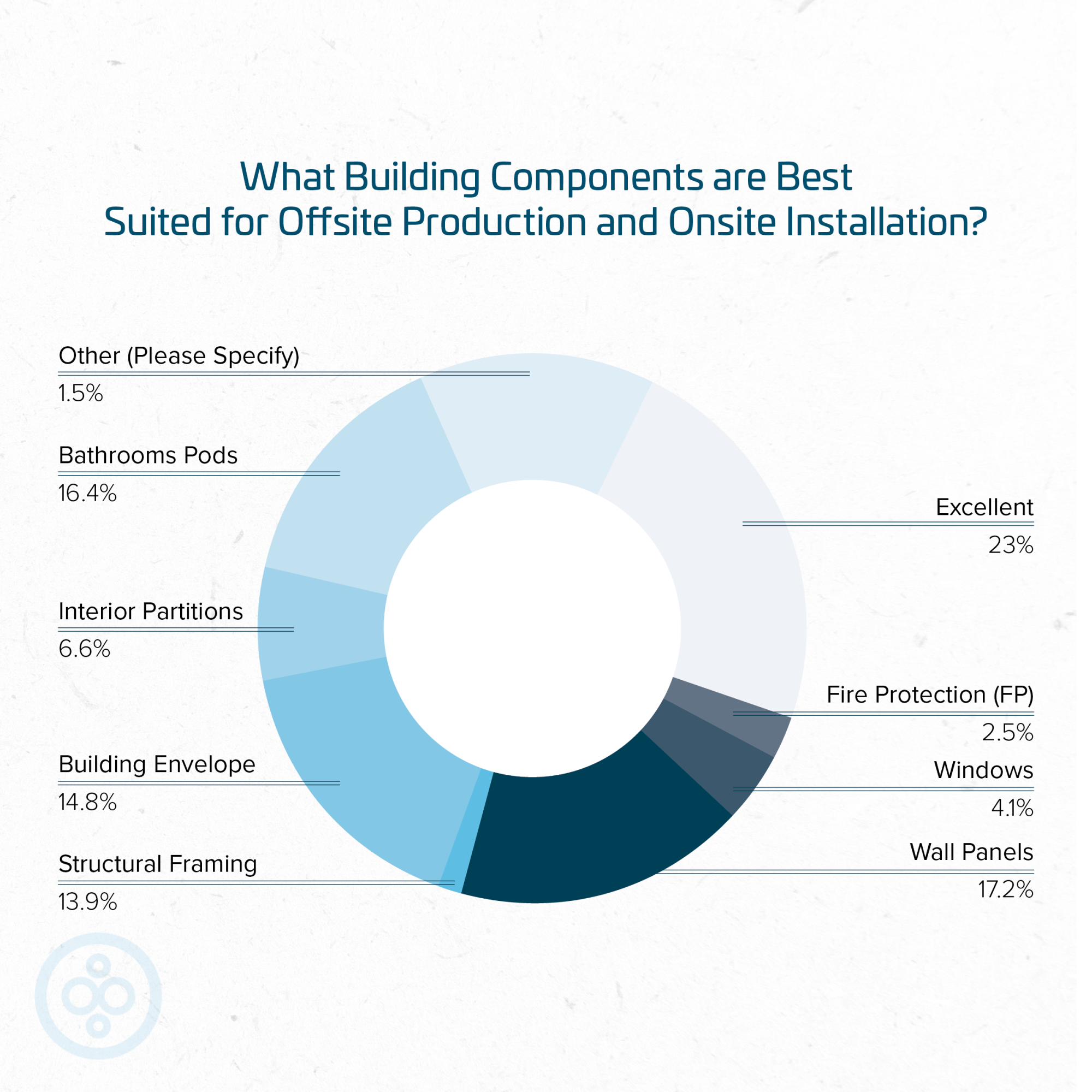

When asked what components were best suited to modular and prefab construction systems, contractors pointed to MEP (23%), wall panels (17.2%), bathroom pods (16.4%), building envelope (14.8%) and structural framing (13.9%) — which is much in line with last year’s report. It was the same consistency when asked what components didn’t suit the building approach.

“There were several materials that survey respondents didn't feel worked as well for off-site construction,” the report reads, “such as hybrid components, concrete, cement fiber, masonry units, floor covering and glass.”

While this consistency reaffirms some factors (i.e., that certain components are better suited to off-site construction so far as the technology and factories supporting the industry currently exist). But Wrenn, who leads the company’s off-site research, specified the areas of construction where off-site techniques are being most implemented.

“Off-site construction has seen the most growth in highly repeatable sectors, such as data centers or multifamily structures, often composed of standardized units or components,” said Wrenn, adding that he’s also seen an uptick in off-site residential. “Many startups entering the off-site space specifically target this segment as a response to the dwindling stock of affordable housing.”

Visit builtworlds.com.

Images courtesy of BuiltWorlds