All the time, effort and energy invested in winning a good construction contract or building a loyal customer relationship, which allows you to negotiate on a project, is wasted with an inaccurate or incomplete estimate. When this happens, firing the estimator will likely do your construction business more harm than good, as you need to continue bidding on a large volume of projects to keep the pipeline full. So, instead, you must help your estimator prioritize.

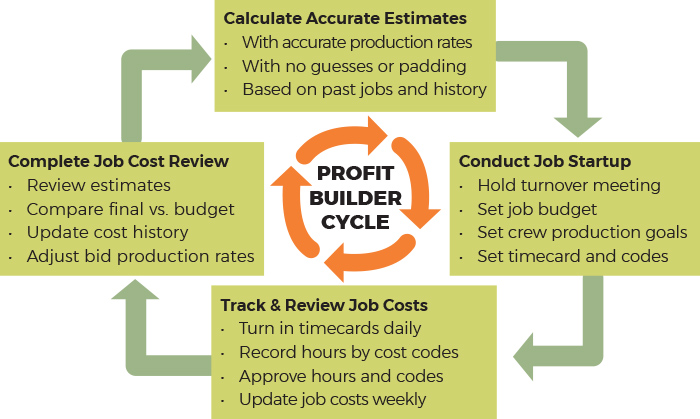

Winning work is not the role of the estimator. The estimator’s role is to prepare an accurate budget within 1 or 2 percent of what the project will cost to build. Then, the management team’s guidelines, goals and strategies determine the added overhead and profit markup, completing the final bid amount. Ideally, the only variables on any bid should be the difficulty factor, overhead and profit markup. Look to Figure 1 for an ideal profit builder cycle to improve estimation accuracy. Along with this cycle, you might also consider the following four ways to help your estimator prioritize his or her tasks to create more accurate bids and win more work.

1. Calculate Accurate Estimates

Accurate estimates are based on the real field-production costs of labor, equipment and supplies required to complete each project. The estimated costs are based on a detailed takeoff of all the parts and pieces. Job costs must be determined via breaking down work by phase, type and production, so a big part of an estimator’s responsibility is to make sure the bid rates are updated and accurate according to changing variables, including:

- Accurate labor burden rates—Each employee has a different burden rate based on their benefits, age, dependents and tenure at the company. Review all of your field employees’ burden rates for accuracy and be sure to factor in accurate taxes, workers’ compensation insurance, medical insurance, liability insurance, vacation, union dues, safety training, overtime and downtime.

- Accurate crew bid rates—Use different crew rates to bid different projects based on what or who the job needs to perform the different types of work it requires. Figure different crew sizes and make-ups to determine your accurate man-hour crew bid rate. You’ll find your bid rate varies considerably for different field crews and teams.

- Accurate equipment rates—Calculate the actual ownership cost for each piece of equipment, from trucks to small machinery. Total the initial purchase price for each piece of equipment plus interest, maintenance, gas and insurance over the life of the equipment. Dividing this total cost by the expected number of billable hours you will be able to charge over the life of the equipment will produce your accurate equipment cost per hour. Then, add your overhead and profit markup for an accurate equipment bid rate. Keep track of how much work or production a typical piece of equipment can perform per hour.

- Accurate general conditions and mobilization—Many poor estimators don’t verify what their general conditions or mobilization really cost on projects, instead guessing or using a percentage for the cost while referencing outdated averages. For example, even a temporary toilet invoice amount varies by the number of services per month plus delivery fee. Accurate estimating must include a review of what general conditions or mobilization actually costs, utilizing field input.

- Accurate overhead—Divide your total annual overhead cost by your total projected annual job costs for every job you will build (not sales volume). This percentage will equal the actual overhead recovery markup you need to recover all of your overhead expenses for the year. For example, $800,000 projected total annual overhead divided by $5,000,000 projected annual job costs equals a 16-percent overhead markup for overhead recovery. Don’t get trapped into thinking you can use an industry average, such as 10 or 20 percent.

- Accurate profit markups—Start every year by deciding how much pre-tax net profit you want to make over the next year. A good rule of thumb for contractors is to aim for a net profit of a 40- to 50-percent return on your total annual overhead budget. To determine the profit markup required to hit your goal, divide your total annual projected costs by your annual profit (e.g., an annual net profit of $400,000, divided by a projected total annual job cost projection of $5,000,000 equals an 8-percent required profit markup).

Figure 1. Profit Builder Cycle

Figure 1. Profit Builder Cycle2. Hold Job Startups

To start every project right, hold a pre-job meeting in which you turn over the job from estimating to the project team. Gather the estimator, project manager, superintendent and foreman together to review the estimate, scope of work, inclusions, exclusions, schedule and contract terms. Have the foreman review the project scope, plans and estimated labor hours prior to the meeting. Then, he or she can help set and agree to the project goals and production budget. For labor and equipment items, develop the job budget and production hours for each cost code for your crew to achieve.

3. Track & Review Job Costs

Start by gathering accurate information from the field foreman and crews. Divide timecards into the cost codes you want to estimate with and keep track of and have them filled out daily. The simplest method is to utilize time-tracking software on tablets or cell phones that integrate with your accounting system. Have the foreman record and approve hours per cost code by task worked on. Have the project manager review and approve the time cards to make sure information is accurate and coded properly before it goes into the accounting system. Set up your job-cost tracking system to develop weekly scorecard production-hour reports. The production scorecard must show the total budgeted hours, hours spent to date, and the projected over- or under-budget amount. Review your production scorecard every week with the crew foreman, superintendent and project manager to discuss the current status and how to keep your project on track to hit budget targets.

4. Complete Job-Cost Reviews

Upon completion of every project, the estimator and project team should review and discuss the actual final costs and hours spent versus the job budget and bid production rates estimated for each cost code. This will allow the estimator to adjust the cost history library and improve the estimated production rates for future bids.