Compact equipment technologies have changed dramatically over the years. Today, manufacturers are designing highly productive machines and adding more sophisticated features to allow business owners to complete jobs in new and innovative ways.

Wireless communication, object avoidance, touch displays, remote-control operation and attachment technologies are just a few advancements that have helped make compact equipment more productive and user friendly. Each of the following enhancements help increase productivity, and they take the guesswork out of manual labor while providing additional safety.

Remote-Control Operation

As innovation takes a forefront in the compact equipment industry, technologies like remote-control operation are continually becoming more advanced. The portable technology previously only worked by using a transmitter strapped around the neck of an operator.

While that’s still a viable option, some compact equipment manufacturers have created remote-control operations that can be used via mobile app on a smartphone or tablet. With this advancement, you don’t need to plan out when you’ll be using the technology on a jobsite. Instead, you can utilize your smartphone at a moment’s notice.

Remote-control operation is primarily used for compact track loaders and skid steer loaders with joystick controls and offers several advantages—even if you have to use a transmitter. The primary benefit is the ability to have complete visibility of the machine without being in the cab. By standing outside your machine, you are able to see every angle and adjust as needed, which leads to more effective operation and more control when operating attachments.

With remote-control operation, you can also benefit from increased project productivity by single-handedly taking care of jobs that often require two people. Additionally, the technology enhances operator comfort for a more inclusive working environment. If your operators are unable to sit in a cab for an extended period of time, or are unable to climb into the machine, they can work outside the cab without losing productivity.

Wireless Communication

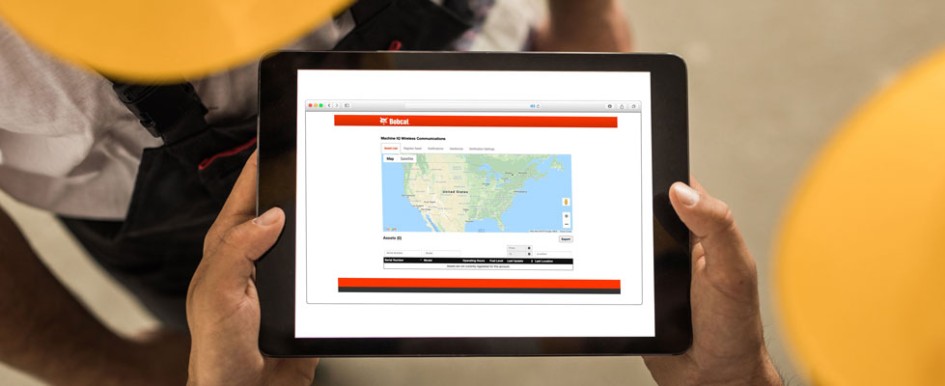

An essential feature in the compact equipment industry is wireless communication technology, also referred to as telematics, which allows you and your operators to maximize uptime and can provide better peace of mind.

The technology works with electronic sensors in your machine to collect machine-specific information and send it out via wireless network to a mobile device or computer. The electronic sensors can track essential machine data, such as the number of hours of operation and critical service codes.

This vital information will let you know when your machine is in need of maintenance. Some wireless communication technologies can transmit your information to your dealer, so if your machine registers a critical code, your dealer will be alerted. Then, they can contact you and dispatch a service technician if needed, allowing you to minimize your downtime.

In addition, the sensors can track fuel usage. With accurate information on fuel usage, you can have a better line of sight to when your equipment is working and when it is idling, which, in turn, can boost productivity. You can also increase your equipment security with wireless communication technology.

By logging into your wireless network, you’ll be able to see your equipment’s exact location thanks to a GPS tracking system built into most modern machines. Object Avoidance One of the latest technologies to hit the compact equipment industry is object avoidance. This advanced technology is simple to use and works by preprogramming avoidance zones.

Equipment manufacturers have the ability to preprogram avoidance zones in a variety of ways. However, all object avoidance systems work in a similar manner by either sending out an alert to an upcoming obstacle or automatically moving the machine to avoid that obstacle. This technology will allow you to tackle any job with ease, as it helps to create a safer work environment and increase productivity on-site.

Some systems work by having the operator take pictures or mark points on a map of jobsite obstacles to create a digital barrier. In addition, with particular object avoidance systems, operators can also select individual objects they want the machine to avoid. The technology then interfaces with the machine to avoid user-defined obstacles.

Other object avoidance systems work similarly to those in the automobile industry, by using vehicle communications to alert the operator when they’re getting too close to another machine.

Touch Displays

In compact equipment, touch-screen displays enhance a machine’s functionality to provide critical information to you and your operators. They offer device connectivity, can improve security and can often improve visibility when accompanied by a rearview camera.

With touch-display technology, you can observe fuel levels, coolant temperature, engine revolutions per minute, hydraulic flow and onboard diagnostics, which will allow you to optimize uptime and serviceability. Additionally, with select touch displays you can monitor and position machine attachments and track operator productivity in detail.

To improve security, touch displays allow compact equipment to be integrated with keyless start systems to help minimize the risk of theft and eliminate the need for keys. Operators can start the machine by entering a password and then pressing the “start” button. Passwords can easily be changed, and multiple passwords can be assigned if necessary. Attachment Technology Advanced attachment-mounting systems can match operator preference to the task and act as the ultimate timesaver.

Hydraulic-activated systems allow you and your operators to secure attachments within seconds by pressing a switch inside the cab that automatically connects the hydraulic lines. This faster and easier method to change out attachments eliminates the need to get out of the machine and manually secure an attachment.

There are a multitude of compact equipment technologies available in the market, so make sure you find the right tech that fits you and your business.