The construction industry is one of the most competitive sectors, driven by tight profit margins, strict deadlines, rising material costs and increasing client expectations. Contractors face constant pressure to deliver projects on time and within budget while maintaining high standards of safety and sustainability. Effective resource management, including equipment and labor, is crucial for staying competitive in this challenging environment.

The good news is that advanced technologies are starting to play more of a transformative role in simplifying project and site management efforts. Beyond fleet management, these innovative products and services help contractors save time, reduce fuel consumption, improve safety and ensure overall project success. From real-time jobsite visibility tools and performance tracking to sophisticated telematics systems and beyond, modern construction technologies offer a wide range of benefits that can streamline operations while boosting productivity.

Start With Better Jobsite Visibility

It goes without saying that comprehensive jobsite safety is the top priority. That often starts with operator visibility, which is why so many manufacturers are putting more research and development into technologies that help operators “see” more of the work environment around them. Some tools can provide a clear, real-time overview of all vehicles, machines and personnel on-site, which can greatly enhance decision-making and coordination. Intelligent positioning services help contractors make less risky, more efficient choices by displaying the exact location of all assets, whether they’re brand-specific machines, support vehicles or temporary site visitors.

By offering total traceability, these tools also help optimize traffic flow across a jobsite, reducing congestion, travel time and fuel usage. For example, a contractor using this type of technology can identify bottlenecks and adjust equipment deployment for smoother operations. Some tools even allow a site manager to set speed limits that are automatically applied to certain machines. Instantaneous communication of critical site updates — such as restricted zones or precautionary alerts — also contributes to a safer work environment.

Track Performance in Real Time

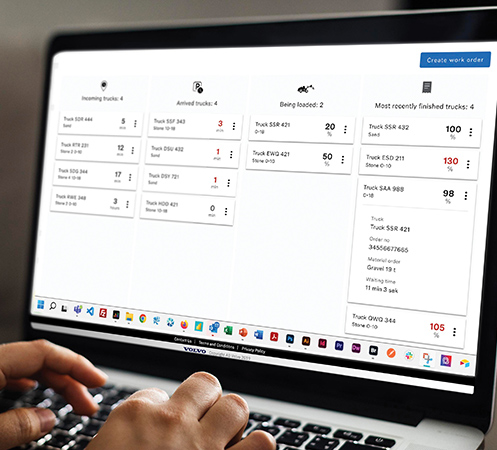

The ability to track and analyze operational data is also essential for maximizing productivity and fuel efficiency on construction sites. Tools that provide real-time data on production levels, fuel consumption and machine cycle times enable contractors to make data-driven decisions that keep projects on schedule and within budget.

Oftentimes, multiple tools can be combined to provide contractors with a more well-rounded view of what’s happening. Contractors can visualize both real-time positioning and performance data for a holistic view of their operations,enabling fact-based adjustments on the fly.

Eliminate Costly Rework

Modern in-cab assist programs aren’t new, but their popularity among operators seems to be gaining momentum, even among the more seasoned pros. Also referred to as machine control systems, these technologies empower operators with immediate guidance to enhance accuracy, reduce costly rework and save fuel. They provide operators with information that improves task execution and ensures that the right machines — and machine features — are used appropriately.

For example, some tools can help an excavator operator dig to the right depth the first time, while others allow wheel loader operators to track real-time load data to prevent overloading. There are similar technologies available for articulated dump trucks, soil and asphalt compactors, and so on.

Machine control systems not only boost productivity but also enhance safety by reducing operator error and unnecessary machine movement, which means less fuel is burned and operational costs are minimized.

Find a Telematics Solution That Works for You

Telematics systems have become a cornerstone of effective project and fleet oversight by providing remote monitoring capabilities that improve logistical control and decision-making. These systems collect data on machine health, fuel consumption and usage patterns, allowing fleet managers to address maintenance needs and prevent costly downtime.

Some telematics platforms require contractors to monitor data and make timely decisions on their own — but if that becomes too cumbersome, issues can get overlooked or ignored. The good news is that there are telematics solutions that do a lot of this work on the back end, filtering data and delivering only the most critical machine alerts to fleet managers and dealers. By eliminating nonessential fault codes and providing clear recommendations, advanced telematics systems help companies maintain uptime while reducing data complexity.

Some platforms provide fleet utilization reports, allowing managers to identify underused equipment, adjust fleet size and make sure the right machines are deployed for the right tasks. This proactive management not only extends equipment lifespan but also improves project efficiency by keeping machines in peak working condition.

Key Takeaways

Intelligent technologies are reshaping the way construction companies manage projects and sites by helping them focus on productivity, fuel consumption, safety and operational efficiency. Key tools to consider include the following:

- Jobsite visibility tools — Real-time positioning systems can help optimize jobsite traffic flow and minimize idle time while improving safety.

- Performance tracking solutions — These data platforms offer insights into production and fuel efficiency, allowing proactive adjustments.

- Machine control systems — These in-cab tools empower operators with on-the-spot guidance for more accurate and efficient work.

- Advanced telematics — Proactive monitoring by an original equipment manufacturer (OEM) simplifies data management, helping contractors monitor and act on the most critical issues in a timely manner.

By leveraging technologies like these, construction firms can gain a competitive edge — maximizing both operational efficiency and profitability. As the industry continues to evolve, embracing data-driven solutions will be vital to building smarter, more sustainable projects.

All-new fleet management technologies are undoubtedly on the horizon, so keep an eye out for innovations that can further transform how you manage your projects, stay competitive and meet the ever-evolving demands of our industry.