Sustainability within the construction industry can encompass everything from project design, build and waste removal, to what materials and fleet assets are used. A significant amount of focus around sustainability is on electrification of both vehicles and equipment, but to build a solid sustainability strategy, it’s imperative to also consider other aspects — such as the efficacy of green materials — and gain a clear understanding of risks.

Guylaine Desmarais, Richard Trempe and Mario Gonçalves, the authors of a research study out of Oak Ridge National Library, outlined one such risk: “A green roof was incorporated into the design of [a building]. … Within two years, water infiltration was reported. The investigation revealed that the aluminum base of the plumbing vents was perforated, at the junction with an extension sleeve. To accommodate the extra height due to the planting medium, it had been necessary to extend the plumbing vents. The problem is that the sleeves were made of stainless steel, which is a noble metal in comparison to aluminum. The combination of these two metals with a very moist environment (the planting medium) led to galvanic corrosion.”

With a growing number of available green materials, assets and technologies, and as more data on these become available, sustainability planning can be tailored more closely to the business’s needs to ensure a smooth transition.

Pros & Cons of Going Green

Weighing the pros and cons is a helpful step in most any endeavor, but it can have the added benefit of helping construction businesses prioritize short- and long-term goals. This is especially beneficial in creating five-, 10- and 15-year plans, which can be adjusted over time as specific goals are met or challenges arise.

Some pros to consider include:

- Regulatory compliance — Aligning with local, regional and/or national sustainability initiatives can help businesses comply with new and incoming regulations.

- Potential cost savings — On the fleet side, electric assets may offer reduced fuel and maintenance expenses.

- Enhanced reputation — Businesses focused on sustainability may gain higher public standing, which can translate to new business opportunities. “Sustainable construction is an approach widely sought by governments, environmentalists and other stakeholder groups who recognise its benefits,” according to Science Direct.

Look at the pros in terms of what the business is trying to accomplish. What do you hope to gain by moving toward sustainability, and what is the best path forward that factors in both goals and cost?

Some cons to consider include:

- Higher upfront costs — Investing in green materials and tech typically requires a significant upfront investment, which may pose financial challenges. On the fleet side, fluctuations in crude oil prices can offset fuel savings associated with electric vehicles (EVs), which should be taken into account when evaluating the overall cost-effectiveness of fleet electrification.

- Increased risk of asset damage — EVs may be more susceptible to damage from rough terrain and jobsite conditions, potentially leading to higher repair costs, while green materials like concrete can increase drum corrosion.

- Product understanding and efficacy — Lack of understanding has so far played a significant role in building enclosure failures caused by issues like mold and reduced structural integrity due to water damage. Product changes often mean process changes, so knowing how certain green materials and assets operate — including the differences in form and function from their standard counterparts — is critical to success.

Look at the cons in terms of challenges that need to be addressed proactively. Will you need to reallocate a portion of

the budget to offset higher purchase costs, and if so, from where in the budget can these funds be pulled with the lowest impact?

Building on a Strong Foundation

With sustainability goals and challenges firmly in place, it’s important to conduct thorough research into the green material or asset you’re looking to procure. How does it stack up to current materials or assets in productivity and efficacy, and what potential impacts might it have on equipment? Consider factors such as abrasiveness, viscosity and corrosiveness to ensure current equipment can handle the new conditions. You may end up having to switch to models that are designed to withstand the unique challenges posed by sustainable materials.

Working closely with suppliers and equipment manufacturers is a great way to address any compatibility issues or concerns related to sustainable materials, as they can provide guidance on equipment selection, maintenance best practices and product recommendations tailored to the specific needs of construction fleets adopting sustainability practices. Be sure to also provide any necessary training and education for construction crews on the proper handling and use of any new materials, including how they may affect equipment performance and what measures operators can take to minimize damage. Encourage open communication and feedback to identify issues early and implement effective solutions.

Measuring the Value

The transition toward sustainability doesn’t stop at planning or even implementation, but also encompasses measuring the cost versus value of those investments. Businesses can leverage historical data to analyze and quantify the impact of sustainability initiatives on key metrics, such as product and material usage rates, fuel and/or energy consumption, productivity and downtime. By comparing the return on investment (ROI) of green purchases, businesses can make data-driven decisions that align with their long-term goals and objectives.

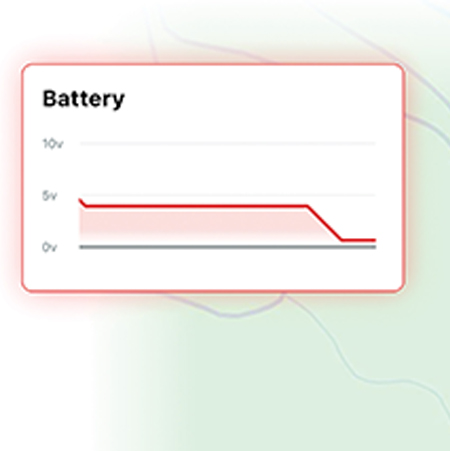

Investing in a robust fleet management software can help businesses easily assess electric asset ROI and performance, and total cost of ownership. These findings can be quickly compared to conventional assets so issues can be addressed in a timely manner, whether it’s mitigating increased asset wear and tear risk or aligning vehicle charging times to off-peak hours.

Addressing unexpected challenges in sustainability requires embracing innovation through strategic planning. By weighing the pros and cons and measuring the value of green investments, construction businesses can make informed decisions around sustainability goals to achieve long-term success.

Images courtesy of Fleetio.