The role of the construction estimator has changed dramatically over the years, particularly for those employed by general contractors (GCs) or construction managers (CMs).

It used to be that the estimator's primary responsibility was to perform a complete quantity "take-off" and price the entire project before accepting subcontractor and vendor bids. Now, particularly for large GCs and CMs, estimators are expected to do much more. Expectations now include "filling in the blanks;" defining scopes of work; assessing alternative materials, systems or methods; and managing the intent of the design team and desires of the owner.

The rapidly escalating cost of construction, lack of resources and lack of bidder interest further complicate the role of the estimator. How can contractors best adapt to these enhanced expectations and provide true preconstruction value to their clients while differentiating themselves from their competition?

Project Delivery Method Affects Preconstruction Services Role

The delivery method selected by a construction owner has tremendous impact upon the definition of the contractor's preconstruction role and whether any preconstruction services beyond estimating will be required at all. Contractors and subcontractors will typically experience one of four project delivery methods on most of their projects:

- Traditional Design-Bid-Build (lump sum bid) based on completed bid documents

- Construction Management-Agency where the trade contracts are directly with the owner

- Construction Management @ Risk with a Guaranteed Maximum Price (GMP) based on less than 100 percent documents

- Design-Build with all design and construction responsibility combined.

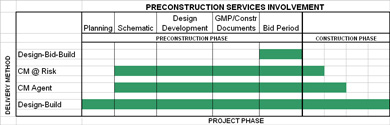

Table 1 indicates the relative level of preconstruction involvement required of contractors and subcontractors for each delivery method. Each construction project is unique and owners approach the selection of their delivery method and construction partner differently, but the recent trend toward more construction management and design build project delivery demands greater estimator capability than traditionally required with Design-Bid-Build.

When owners have traditionally put their projects "out to bid," the focus of the estimating team would be limited to a very short and very intense bid period between receipt of the documents and the day of the bid. Depending on the project, this may be only a two-to-four week period of time. The objective of this bid period would be to win the project by being the lowest cost bidder. Keys to success in lump sum bidding include receiving as many bids as possible, knowing in great detail the quantities of materials required, including only what is clearly necessary and maintaining low overhead costs and fees.

In contrast to this approach, Construction Management (CM) and Design-Build project delivery methods demand the involvement of the estimator or preconstruction manager for a much longer period of time, typically months and sometimes years prior to the actual start of construction. In addition, CM and Design-Build projects are often "fast tracked" or bid in packages allowing work to begin much sooner and to proceed while other portions of the project are still being designed. The result is the preconstruction and estimating activities overlapping construction activities for months or even years on large projects. Throughout this process, multiple estimates are created, updated and frequently refined based upon new design information or alternate materials or systems for portions of the work not yet bid.

Many CM firms employ preconstruction managers, essentially preconstruction project managers, to lead the project through this period prior to the start of construction. Although many preconstruction managers possess an estimating background, more and more are field operations staff seeking a career change from onsite project management roles. Preconstruction managers in firms handling large projects may only be able to handle two or three projects at a time and may not even do any estimating themselves. Rather, they act as the manager of internal resources of the estimating department to produce progress estimates at design milestones, evaluate material and system costs, review document progress and coordination, build and maintain subcontractor and vendor relationships and serve to efficiently hand off the project to the project manager and superintendent at the start of construction.

Design Milestones

The nature of project delivery methods beyond traditional Design-Bid-Build require preconstruction manager involvement in the project as the design is developing through key stages. Although universally accepted definitions of these document development stages are not common, the implications for the preconstruction team at each phase can be generally outlined as follows:

Planning: (Also known as program) includes a comprehensive listing of all new needs and spaces for the building.

Conceptual: At the conceptual stage, some preliminary form has been contemplated for the building, including number of floors, total gross area, potential site, etc., and hand sketches may be available to clarify the design intent.

Schematic: At the schematic document (SD) stage, it is common to have single line scaled drawings of typical floor layouts, as well as a narrative description of the major structural, mechanical and envelope systems of the building.

Design Development: At this Design Development (DD) point, the design of the project is close to being locked down and plans for all disciplines such as civil, architectural, structural, mechanical and electrical are included. Subcontractor and vendor estimating assistance should be sought for all areas of the project estimate.

Construction Documents: Although an owner can theoretically be offered a Guaranteed Maximum Price (GMP) at any point in the design process, the desire to minimize allowances, contingencies and changes will usually dictate that the GMP be established based upon Design Development or later documents.

At each of these stages the preconstruction manager creates estimates that increase in detail. Along with the increased detail of each succeeding estimate, comes a corresponding decrease in contingency and qualifications that are necessary. A key owner and designer expectation of the preconstruction manager is the ability to clearly identify what changed and why it changed from previous estimates. A detailed variance report allows for clear identification of changes to the estimate.

It is essential that all progress estimates, starting from the very first one delivered, reflect the total anticipated construction costs regardless of what is shown. Unlike the Design-Bid-Build approach, owners employing construction managers or design-builders have little tolerance for hearing "it wasn't shown. It is the job of the CM preconstruction manager to "fill in the blanks" based on experience, knowledge and historical data so that the owner and design team are not surprised by escalating numbers as the design is finalized. Herein is the fundamental difference between the role of the preconstruction manager in CM or Design-Build and an estimator in a "hard bid" estimate. The preconstruction manager is expected to look out for the interests of the owner from the very first estimate by assuring the estimate is complete and reflects all that is required to build the project whether clearly indicated by current documents or not.

Beyond Design-Bid-Build, estimating becomes a process rather than a singular bid day event to be managed. This extended and enhanced role demands that preconstruction professionals wear many hats beyond that of just "estimator". Unlike Design-Bid-Build estimators, preconstruction managers at early stages of design rely on historical data and experience to quickly develop required alternate approaches and solutions from similar projects.

Multiple Skills Required

Preconstruction managers in CM or Design Build delivery are called upon for much more than just quantity take-off and estimating.

Preconstruction Phase Schedule Management is one of the key roles of the preconstruction manager. Creating a realistic and detailed schedule for all design, approval, estimating and purchasing activities to ensure that construction activities begin on schedule is the primary objective of the preconstruction schedule. The Precon schedule must reflect what is expected of the design team, CM and owner so that packaging and scoping of the work can be accomplished through documents that address required information at each stage of the design process. For this reason, it is critical that the preconstruction manager be involved in the project as early as possible to coordinate deliverables and expectations with the design team.

How the Precon manager communicates the scope of work to bidders has a significant impact upon what documents the design team will be expected to produce and when they will be needed. Some CM firms will write detailed scopes of work for specific bid packages and receive sealed bids for each package. These scopes of work may combine work that might not otherwise be performed by one subcontractor, such as in a general trades package which may include work from more than a dozen specification sections. Another common approach to defining the work and soliciting bids is a carry-over from the "hard-bid" Design-Bid-Build delivery method whereby subcontractors and vendors bid work to the CM by specification section and the content of their bids is then compared in great detail by the CM using a scope sheet or bid tab sheet.

The preconstruction manager also plays the part of document reviewer and advisor for constructability and value analysis. Constructability reviews can serve multiple purposes, but the most common are evaluating how constructible the design is (how easily it can actually be built without incurring unnecessary cost or schedule premiums) and how complete and coordinated the documents are. The first review is aimed at cost savings and time savings by ensuring that considerations such as site logistics, access, staging, materials and systems are considered in the design. The later review is aimed at answering two key questions. Are the documents sufficiently clear and complete to both bid the project and to build the project? This review is accomplished by interdisciplinary reviews of progress sets of documents in an attempt to identify conflicts or ambiguity on the plans prior to design completion and before they become issues in the field.

Value Analysis, or value engineering, as it has been commonly known in the past, is another preconstruction role that seeks to improve the value of a material or system in the building by accomplishing or delivering more at less cost. Unfortunately, many contractors in the past have slashed scope and dramatically altered architectural intent under the banner of "value engineering" thinking that "VE" is merely a cost reduction strategy and losing sight of the value proposition. The result has been many designers becoming wary of contractor value management suggestions. A key formula to bear in mind regarding Value Analysis is V=F/C, or value equates to function divided by cost. This formula definition of value makes it clear that the value of a material, system, or building can be increased by increasing the function, decreasing the cost or both. Simply making the building smaller or removing scope does not increase value since these changes reduce function.

Essential in the discussion of value is the consideration of life cycle costs. Decisions on critical systems or materials are often naively driven by initial construction costs alone without regard for the operations and maintenance costs over the life of the building. Rationalizations by owner's representatives overseeing construction for such decisions often include the fact that maintenance is funded from another budget or that maintenance is "not my problem." The driving force is typically the desire to get the most building for the least cost at initial construction. The reality is that when a life cycle approach to the project budget is applied, including long-term repair and replacement costs, additional funds for the initial construction are easily identified from repair and replacement savings.

Assisting the owner in managing their total project budget beyond just the "bricks and sticks" construction costs is essential for preconstruction managers. Wise owners seek the entire project team's input on the total project budget as early as possible. Early review of project costs such as environmental assessments, testing services, design fees, permit fees, furniture, equipment, moving, artwork, groundbreaking ceremonies, etc., can help avoid costly redesign efforts later in the project. Redesign may be required if insufficient total project funds are available to both construct the building and finance items similar to the above that may have been overlooked or underestimated.

Preconstruction Services Best Practices

So what can a preconstruction manager do to manage this preconstruction phase with so many expectations? Consider the following best practices to help guide the client and the design team and attract the greatest number of qualified bidders:

Document Decisions: Maintain a tracking log of team decisions throughout the design phase ensuring nothing falls through the cracks. This includes a log or estimate tracking tool that captures every pricing request or design alternative and its status whether approved, pending or rejected.

Variance Reports: Perform each estimate in a manner that will allow an easy reconciliation with previous and future estimates to explain what has changed and why. Few things are more important to the design team and owner than how the price has gone up from that prior estimate.

Bid Lists: Establish a bid list as a collaborative effort with the owner and design team very early in the project. On private projects, this will likely be the list of invited bidders. On public work open to all qualified bidders, the list represents those who you would like to ensure will bid the project. Creating this list from a foundation of trusted subcontractors from both the owner and design team is a great way to facilitate teamwork and early buy-in. The earlier this list can be created, the more impact these subs may be able to have during the critical SD and DD estimates.

A word of caution: Consider carefully the subs who may be asked to provide assistance during these early estimates. If they offer estimate assistance during early estimates they will expect, and should be afforded, an opportunity to bid the project at bid time. If they are only used for estimates and not allowed to bid, they may not offer assistance in the future, or worse, their estimate numbers may not hold up on bid day. All bidders who are allowed to bid must be subcontractors to whom the project team would be willing to award the work if they are low. If not, the subcontractor's time has been wasted and a relationship fractured.

Scope of Work: Provide clear scopes of work to all bidders either via written scopes of work or through scope check sheets that clearly define what is expected. Creating a bid manual incorporating all requirements such as form of subcontract agreement, insurance requirements, safety requirements, general provisions and instructions to bidders is a great way to simplify the review of bids received.

Pre-Qualify Bidders: All bidders should be pre-qualified. Confirm that all bidders have the manpower and financial resources to perform the work, that they have a history of successfully completing similar work, they can meet the project insurance requirements and that their current workload will not impact their ability to perform. It is essential to know whether a bidder has any objections to the subcontract language before, including their bid in any estimate or GMP.

Pre-Bid Conferences: One of the best methods for attracting and retaining qualified bidders is conducting a comprehensive, and well-organized, pre-bid conference. Attendance at the conference can be mandatory for bidders but is typically best defined as "strongly encouraged" to assure that as many bids as possible are received. Key topics that should be addressed are bidding requirements, insurance and contract requirements, site logistics, schedule and safety and health procedures. Publish detailed minutes of the meeting shortly afterwards to all bidders.

Risk Reduction: Bidders are attracted to work that minimizes their risk, particularly in a busy market with many projects competing for their time and attention. CMs can maximize the number of bids received by ensuring, with the design team, that the bid documents are as thorough, complete and clear as possible. Where questions may still remain, it is far better to define allowances that all bidders will carry in their bids to cover ambiguous scope items than to leave it up to bidders to figure out what, if any, amount to include in their bid for unclear areas of their scope. This levels the playing field and relieves bidders of the possibility of either overestimating the risk and pricing the work too high or not bidding the project at all to avoid risk entirely. Allowances also prevent bidders from leaving money out of their bids for work not clearly defined due to their fear of not being competitive if the cost of ambiguous work is included. Allowances shift the risk and reward back to the owner, where it rightfully belongs for scope that is unclear. Unspent allowance dollars revert back to the owner, and additive change orders to the subcontractor cover insufficient allowances.

Escalation Control: Provide a clear and fair way for bidders to account for material and labor escalation in their bids. If market conditions indicate rapidly rising prices, bidders may be unable to hold their prices for the typically specified sixty or ninety days from bid day. If forced to hold their numbers in a volatile market, they will include sufficient contingency to cover the anticipated worst case escalation which either renders their bid too high or one of the "take it or leave it" numbers received on bid day. A better way to handle volatile market pricing is to define a current market index (such as ENR cost indices) for materials or labor subject to rapid increases, and require all bidders to base their bids on that index's current or assumed value. Prior to the contract commitment or the ordering of materials, the bid price can be adjusted based on the current index to eliminate the "guesswork" on the part of bidders.

Post-Bid Interviews: Prior to awarding the contract, it is essential to have a detailed review of scope to determine that bidders have sufficiently covered their required scope of work in their bid. This is the opportunity to ensure that all bids received are "apples to apples" and to ensure that an apparent low bidder will not seek to make up ground via change orders if awarded the work. In public work or if sealed bids are required, there may be limited options for revising the bid number in response to post bid interview findings, yet the process is essential to clearly establish expectations and agreement with the bidder prior to award.

Managing the Process

Considering the scope and length of the preconstruction process, the need for a system to manage this process is clear. Despite the need, there are few tools beyond stand alone estimating, digitizing, scheduling and project management software that can be used to manage the entire process. Most companies struggle to select and implement a standardized estimating application, let alone manage the entire preconstruction process with a unified system.

The fact is that there are limited software options available for managing the crucial preconstruction phase of a project. One of the industry leaders in project management applications, Constructware (www.constructware.com) offers a bid management module to track bid packages and bidders. In addition, project information and document management modules designed as management tools for use during the construction phase can be applied to the needs of the team during the preconstruction phase of the project. Others such as iSqFt (www.isqft.com) have developed focused solutions such as their Private Construction Office for the specific task of bid management and the challenges of distributing bid documents and soliciting and tracking responses from invited bidders. Eos Group (www.eosgroup.com) specializes in preconstruction solutions for the design-build market. They have created Advisor, a web-based project history system that supports the preconstruction processes of budgeting and benchmarking current projects against others that are similar. Another Eos Group solution, Explorer, is a people, process and data management system for preconstruction estimating operations. Still, a comprehensive solution for managing the needs of the entire preconstruction phase with the effectiveness that project management systems address the construction phase has yet to be developed.

Construction firms who seek to differentiate themselves from their competition understand that preconstruction is a worthy focus for their attention and resources. When seeking to contract on more than just a lump sum or "hard bid" basis, organizational capabilities prior to the start of construction must extend well beyond just estimating skill. Despite a market that rarely reimburses contractors for all their preconstruction costs, most owners still expect the involvement of their contractor early in the design phase and rely heavily upon the cost, schedule and design expertise contractors offer to ensure they receive the most from their construction dollar.

Construction Business Owner, February 2007